FTC STANDS FOR FAIR TRADE CASHMERE

We do care - We take, accept and live responsibility.

Own farm - own manufacture - our power.

Own supply chain as a key to sustainability.

We have sustainability in our hands and hearts.

Upcycling for a zero-waste production

Social responsibility and environmental protection

2003 - Foundation in Rosenheim (Germany)

2004 - Logistic centre in Niederndorf (Austria)

2004 - Building of own manufacture in China

2005 - Relocation of Head office to Switzerland

2007 - Start Farmer Protection Program

2007 - Opening first school in Province Shaanxi

2009 - Relocation of the first school to larger Building

2009 - Opening of Goat Breeding Farm

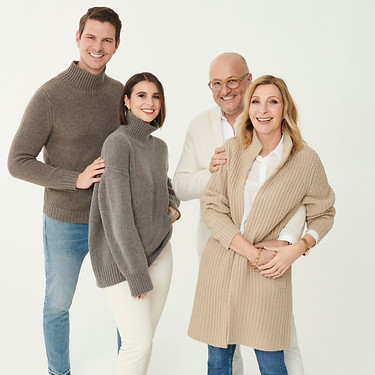

2016 - Entry of the next generation with Jana & Adrian Knezovic

2017 - Ground-breaking of new Farm in Shaanxi Province

2018 - Solar panels at our manufacture

2019 - Change of European buildings to green power

2019 - Oeko Tex 100 certification for our own yarns

2019 - Launch of Upcylcing Project (UpKnit - Upcycling for Uniqueness)

2020 - Physical evidence of the value chain by Haelixa

2021 - Climate neutrality for the entire company, products and processes

2021 - All products are certified with STANDARD 100 by OEKO-TEX®

2022 - All pr ae certified with MADE IN GREEN by OEKO-TEX®

In order to integrate all spheres of sustainability (social, economic, environmental and cultural), FTC® also sees itself as responsible for the living beings involved. It is about a constant exchange, which is also noticeable between people. Different initiatives should enable well-being and improve life circumstances.

-

Swiss Int. FTC Cashmere World Hope School

-

Cashmere Farmer Protection Program

-

FTC® Goat Breeding Farm

-

New Shaanxi Goat Farm

FTC® is really proud to be the owner and manager of its complete supply chain. Starting by the cultivation of the food for the FTC® cashmere goats, and continuing through the whole manufacture processes.

To keep the standards high FTC® works with modern German Stoll knitting machines in its own park. Furthermore, is the building where the carding process takes place is covered with solar panels. Thanks to a modern water treatment plant, the footprint of the dyeing process can be kept as low as possible.

From the fodder of the goats to the treatment and harvest of the fine cashmere - every step is managed and owned by FTC®. Thus, the standards are high and animal welfare made sure.

In northern Shaanxi (China) the new cashmere goat farm by FTC® is being built since 2017. The goal for the new farm in northern Shaanxi is to be an example for sustainability - FTC® works for example with rammed earth to use less emissions and they plant trees as well as vegetables for the local community.

To reduce material waste completely and taking a step further into circular economy, FTC® has worked on a yarn- processing and knitting technology to reach a zero-waste production. The outcome is an upcycled line called «UpKnit – Upcycling for Uniqueness by FTC® ».

Residual yarns from our production are upcycled with our pioneering technique. The the residual yarns are seamlessly joined together. Since these have different colors and a variety in lengths, this results in a multicolored effect with irregular color-sequences. This creates different color gradients and each article from our UpKnit line becomes unique. Especially nowadays, where fast fashion happens, it is difficult to have a unique style and to find an own way to communicate with clothes. Therefore, the UpKnit collections emphasize the uniqueness of our customers.

In these days it’s difficult to justify consumption of new clothes, but the consumer’s need of buying fashion is expected to last. Our zero-waste products enable a good feeling with responsible and conscious consumption. As a vertically positioned company, we monitor and manage every step of the supply chain, so we identify optimization gaps - as happened in this project. UpKnit is just the start, but an important milestone in our purpose of deceleration. In addition, we set an example in sustainability and go a milestone to establish new production standards.

PURE NATURE - UNDYED & UNBLEACHED

Next to the extensive FTC® color card, undyed and unbleached cashmere is offered - in the three colours Natural Cream, Natural Sand and Natural Taupe.

"With the Cashmere-Organic Cotton blend we expand our knitwear collections especially for the warmer months, with attractive prices. When developing the blend, it was important not to abandon our core competence, cashmere, and still offer a cooler, summery feel."

- Jana Knezovic, Head of Product Management at FTC®.

These products are made of 70% Organic Cotton and 30% Cashmere.

The whole FTC® collection is MADE IN GREEN by OEKO-TEX® certified. When you order you will get a fully certified product of the internationally recognized label.

FTC® is convinced that this achievement helps to further emphasize the brand values, also within the brand-owned production facilities and the associated production processes.

To keep the ecological footprint smaller, FTC® has converted its product packaging to recyclable paper bags.

The solid, unbleached, FSC®-certified kraft paper will replace the previous polybags with the aim of reducing plastic consumption, minimising waste and making packaging more environmentally friendly.

The above information is also always available through this QR code. You will find the same QR Code in all the products carelabels and hangtags for the final consumer to inform themselves.